Installation and use requirements of mechanical seals

The requirements of mechanical seals for machine accuracy (take mechanical seals for pumps as an example)

(1) The maximum radial runout tolerance of the shaft (or shaft sleeve) where the mechanical seal is installed shall not exceed ~.

(2) The axial movement of the rotor does not exceed.

(3) The runout tolerance of the combination of the sealing cavity and the sealing end cover facing the surface of the shaft (or shaft sleeve) shall not exceed ~.

Confirmation of seals

(1) Confirm whether the installed seal is consistent with the required model.

(2) Before installation, carefully check with the general assembly drawing to see if the number of parts is complete.

(3) For the mechanical seal driven by the parallel coil spring, the spring can be divided into left and right rotation, which must be selected according to the rotation direction of the rotating shaft.

Installation

The installation method varies with the type of mechanical seal and the type of machine, but the installation methods are almost the same. The installation steps and precautions are as follows:

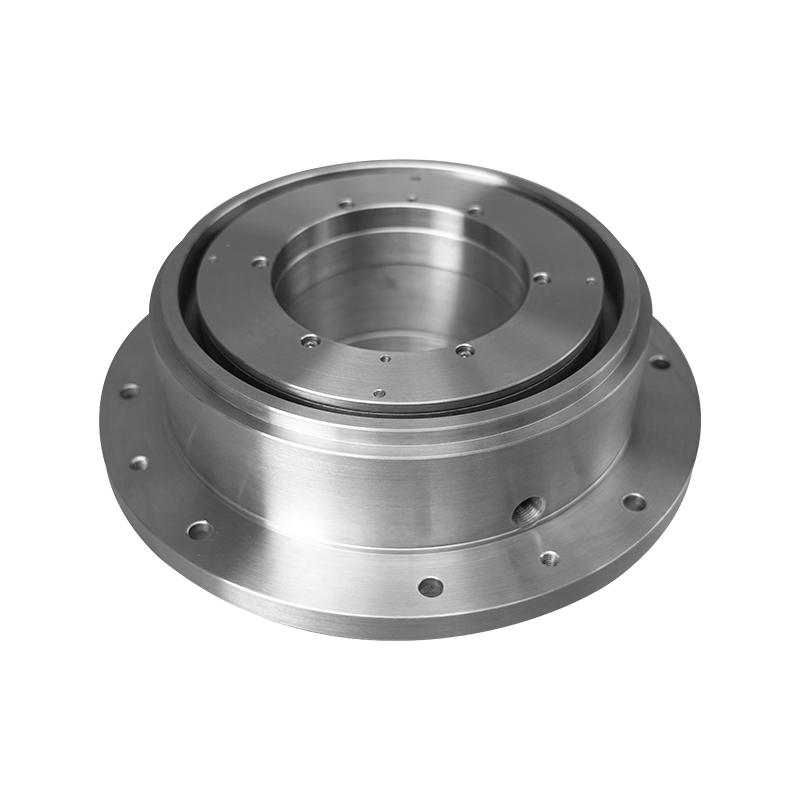

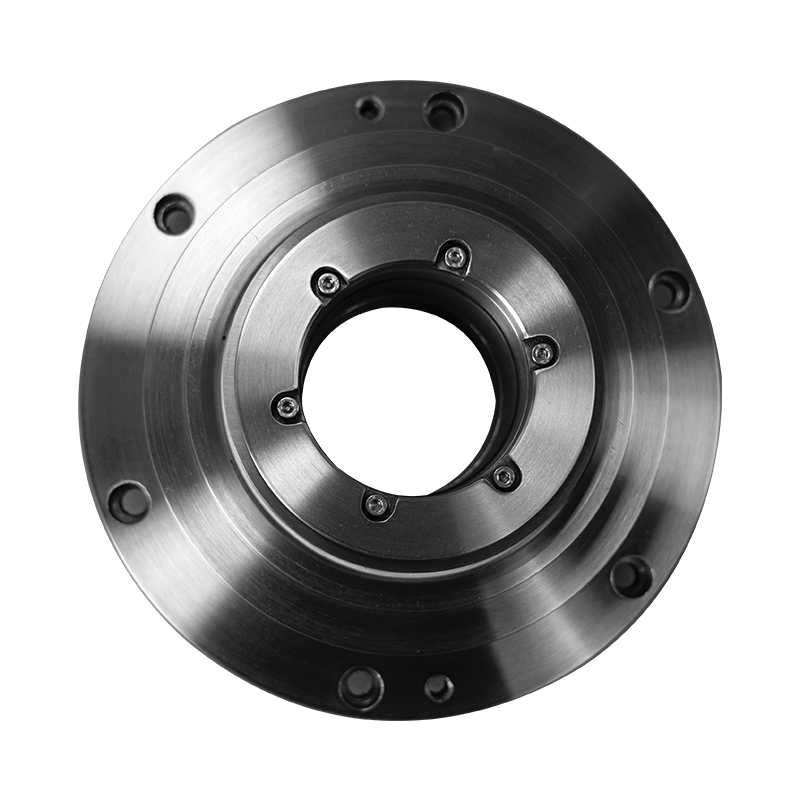

(1) Determination of installation size

When installing, ensure the installation size of the mechanical seal according to the product instruction manual or sample.

(2) Before loading, the shaft (sleeve) and gland should be free of burrs, and the bearing should be in good condition; the seals, shaft, sealing cavity and gland should be cleaned. In order to reduce frictional resistance, the part where the mechanical seal is installed on the shaft should be coated with a thin layer of oil for lubrication. Considering the compatibility of rubber O-rings, if oil is not suitable, soapy water can be applied. The structure of floating static ring without anti-rotation pin should not be oiled, and should be installed in the gland dry.

(3) Install the static ring together with the gland on the shaft first, being careful not to touch the shaft, and then install the moving ring assembly. The set screw of the spring seat or transmission seat should be evenly tightened several times.

Before the gland is not fixed, push the compensation ring by hand for axial compression. After loosening, the compensation ring can automatically spring back without jamming, and then lock the gland bolts evenly.

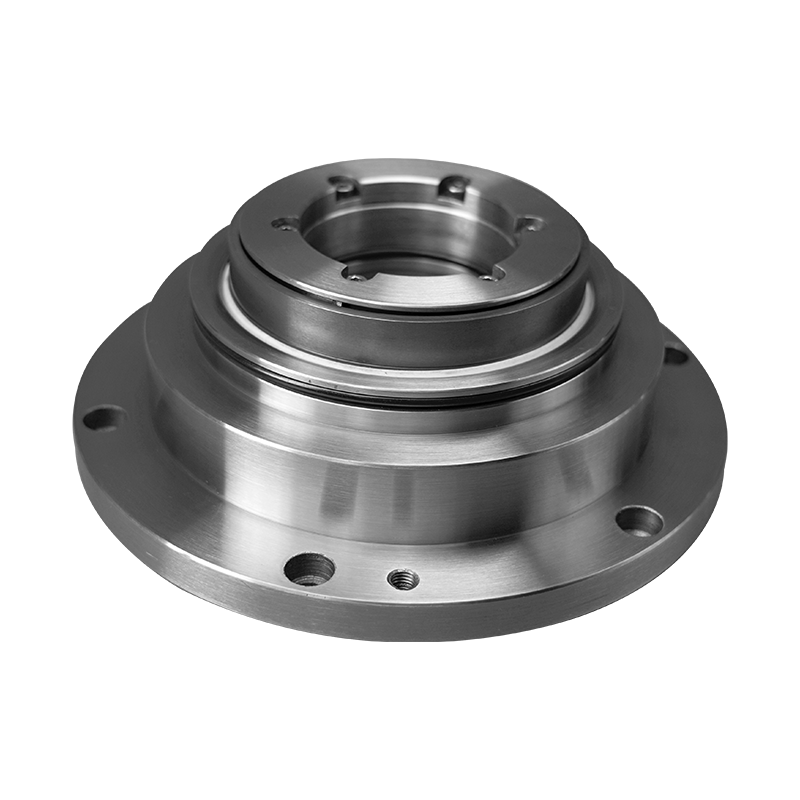

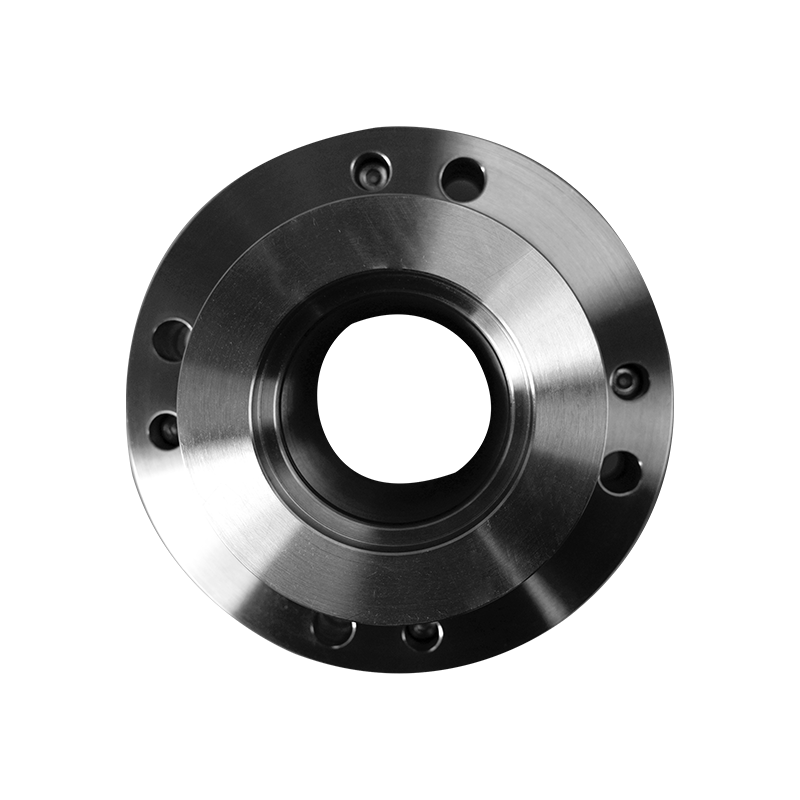

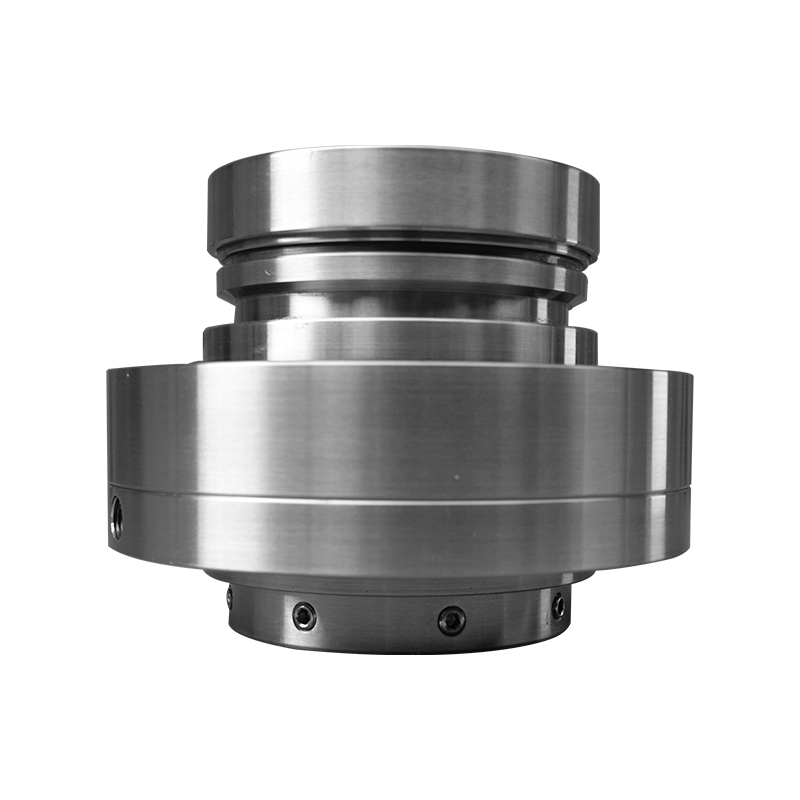

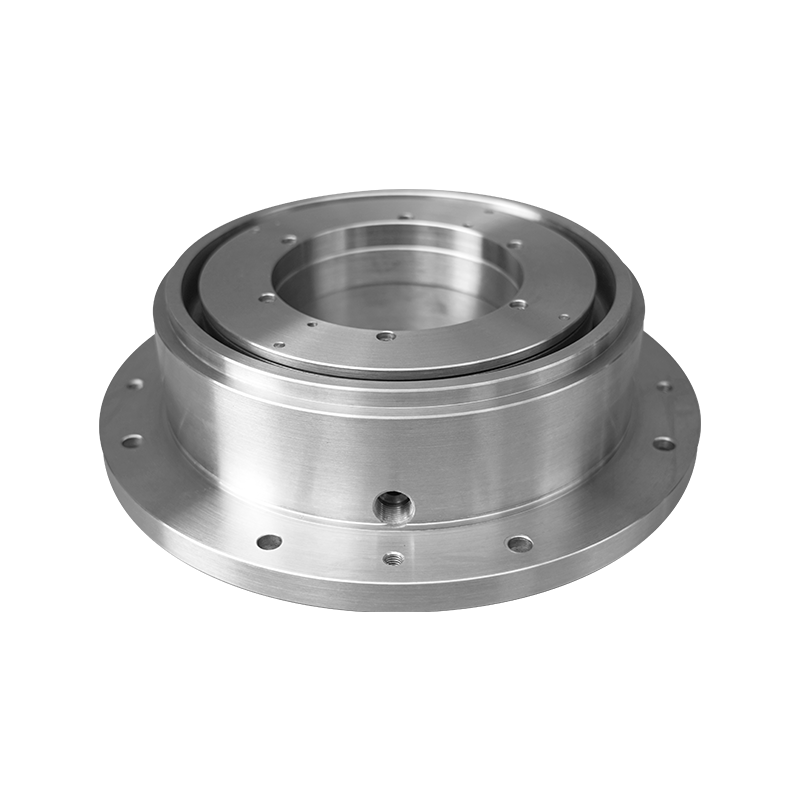

Mechanical seal refers to a seal against fluid leakage formed by at least a pair of end faces perpendicular to the rotation axis that keep fit and slide relative to each other under the action of fluid pressure and the elastic force (or magnetic force) of the compensation mechanism and the cooperation of the auxiliary seal. device.

The elastic loading mechanism and auxiliary seal are mechanical seals of metal bellows, which we call metal bellows seals. In light-duty seals, rubber bellows are also used as auxiliary seals. The rubber bellows have limited elasticity, and generally need to be supplemented by springs to meet the loading elasticity. "Mechanical seal" is often referred to simply as "mechanical seal".

A mechanical seal is a shaft sealing device for rotating machinery. Such as centrifugal pumps, centrifuges, reactors and compressors and other equipment. Since the transmission shaft runs through the inside and outside of the equipment, there is a circumferential gap between the shaft and the equipment, through which the medium in the equipment leaks out. If the pressure in the equipment is lower than atmospheric pressure, the air leaks into the equipment, so there must be a Shaft seal to prevent leakage. There are many types of shaft seals. Because mechanical seals have the advantages of less leakage and long service life, mechanical seals are the most important shaft sealing methods in these equipment in the world. Mechanical seals, also known as end face seals, are defined in the relevant national standards as follows: "At least one pair of end faces perpendicular to the axis of rotation is maintained under the action of fluid pressure and the elastic force (or magnetic force) of the compensation mechanism and the cooperation of the auxiliary seal. A device that prevents fluid leakage by sliding against each other.

Sichuan Daying Seals Co., Ltd. is a comprehensive sealing enterprise mainly engaged in mechanical seal design, sales and service. The company is located in the hometown of "Zhutsutsui", which is known as the fifth largest invention in China - Suining Daying County Industry Centralized development zone, located in the hinterland of the Chengdu-Chongqing-Mian economic circle within one hour. The traffic location advantage is extremely prominent. The company now has a total area of more than 30,000 square meters of production and auxiliary workshops, more than 100 employees, more than 20 engineering and technical personnel, and has strong talent and technical advantages.

After more than 60 years of rapid development, the company has been engaged in the design, manufacture and processing of mechanized agricultural machinery, auto trailer accessories, vehicles, planers, drilling machines and other equipment, and has been transformed and upgraded to the production of mechanical seal series products. The company has complete processing equipment and sophisticated testing instruments, and can customize, design and manufacture sealing products of various specifications and technical requirements for customers. The company's products are sold to domestic petrochemical enterprises such as PetroChina, Sinopec, and CNOOC, and exported to the Middle East and other regions.

In order to enhance the R&D and innovation capability, the company has cooperated with Beijing University of Chemical Technology and carried out fruitful production, learning and research activities. The company has successively passed ISO9001 comprehensive quality management system certification and mechanical seal production license certification. The company is now a member unit of China Mechanical Seal Industry Association and a member unit of the Chemical Industry Special Seal Standardization Technical Committee.

Liu Yiting

dayingkhsy996@gmail.com

Disclaimer: This article is reproduced from other media. The purpose of reprinting is to convey more information. It does not mean that this website agrees with its views and is responsible for its authenticity, and does not bear any legal responsibility. All resources on this site are collected on the Internet. The purpose of sharing is for everyone's learning and reference only. If there is copyright or intellectual property infringement, please leave us a message.

©copyright2009-2020New York Fashion News Contact Us SiteMap