Oil drums are generally made of iron or plastic in the shape of a cylinder. They were first invented by the Germans on the eve of World War II. They are mainly used to carry important military materials - gasoline. It can be said to be a typical product of war. Oil drums are widely used in industrial production. They are often used as containers for chemical raw materials. After the oil drum is loaded with products, the information of the products loaded, such as name, category, ex-factory date, and so on, needs to be printed on the oil drum. How can this information be identified on the oil drum?

The common ways to mark oil drums are pasting labels and printing information with direct ink. The way of pasting the label, the label is easy to fall off in high temperature or humid environments. The printing method of oil drum ink can solve the problems encountered in the labeling method. The traditional printing method of oil drum adopts screen printing.

The process of screen printing is: first make the printed content into a screen, then put the screen on the product to be printed, pour the diluted ink into the screen, scrape the ink with a scraper, and the pattern is printed on the product. After printing the pattern, it is necessary to use drying equipment to dry the ink.

Although screen printing seems to be widely used, the printing process has many defects.

1. Screen printing is inefficient and troublesome. Screen templates are in great demand and need to be updated regularly. There are many kinds. One template for each product. The replaced old template can no longer be used, so it will cost a lot of screen-making costs.

2. Screen printing is not environmentally friendly, and it is harmful to the health of operators. During printing, people will be choked by ink and screen.

3. Screen printing ink is not easy to dry, especially in winter, it is troublesome to be equipped with high-voltage and high-power drying equipment.

4. The operation is difficult. Screen printing needs to allocate ink by itself. If the newcomers are inexperienced, they can't match the ink well, the scraper can't scrape well, and the printing effect can't meet the requirements.

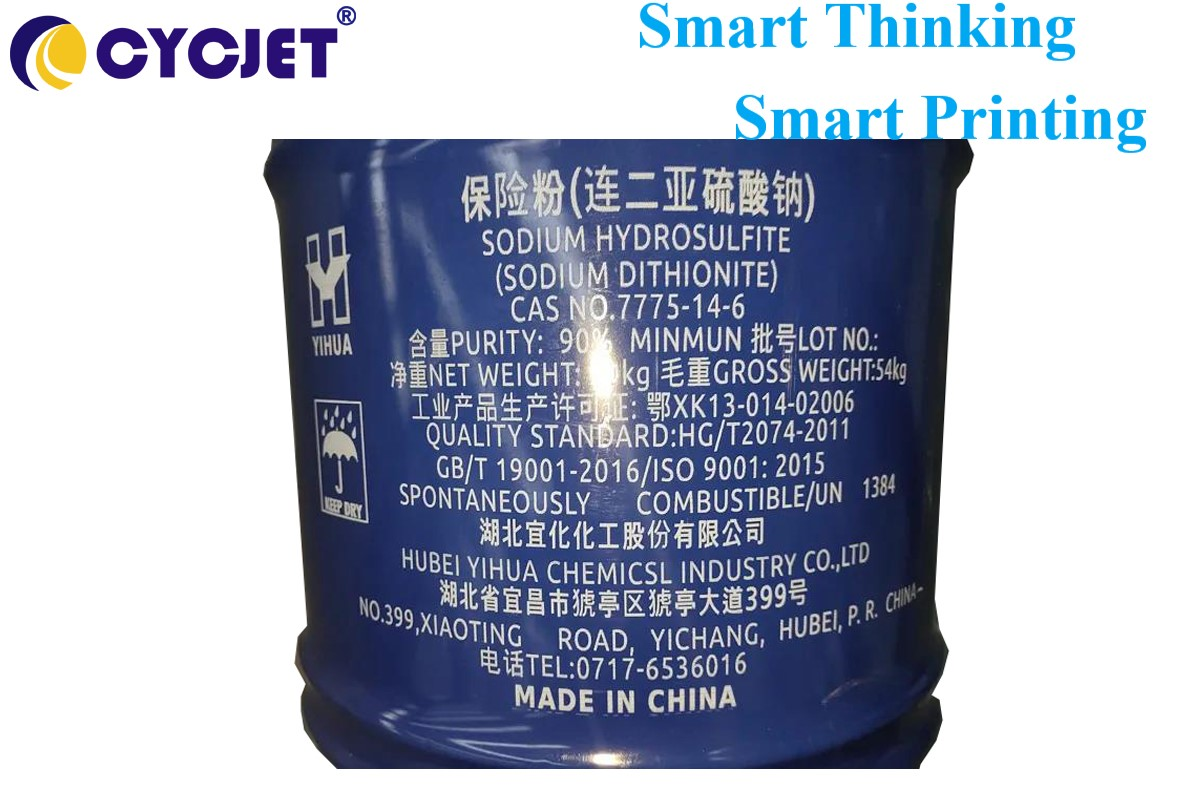

To solve these problems, Yuchang has developed a large format inkjet printer, which has been successfully applied in the field of oil barrel printing. Constant pressure ink supply system and UV ink technology ensure the stability of the machine. After the marking information is sprayed by the inkjet printer, it is irradiated by UV cold light immediately. The ink dries immediately before diffusion, and the adhesion is greatly improved.

Yuchang inkjet printer provides RS232 / WiFi/network port and other communication interfaces, which can connect with various enterprise management systems to realize real-time information transmission and printing and help the construction of enterprise information identification system. In addition to printing characters and icons, the machine can also print one object, one code, two-dimensional code, bar code, and other contents, so as to realize the traceability management of enterprise products.

CYCJET is the brand name of Yuchang Industrial Company Limited. As a manufacturer, CYCJET has more than ten years of experience for wholesalers and retailers of different types of handheld inkjet printing solutions, laser printing solutions, portable marking solutions in Shanghai China.

Contact Person: David Guo

Telephone: +86-21-59970419 ext 8008

MOB:+86-139 1763 1707

Email: sales@cycjet.com

Keywords:

Working video:

Disclaimer: This article is reproduced from other media. The purpose of reprinting is to convey more information. It does not mean that this website agrees with its views and is responsible for its authenticity, and does not bear any legal responsibility. All resources on this site are collected on the Internet. The purpose of sharing is for everyone's learning and reference only. If there is copyright or intellectual property infringement, please leave us a message.

©copyright2009-2020New York Fashion News Contact Us SiteMap