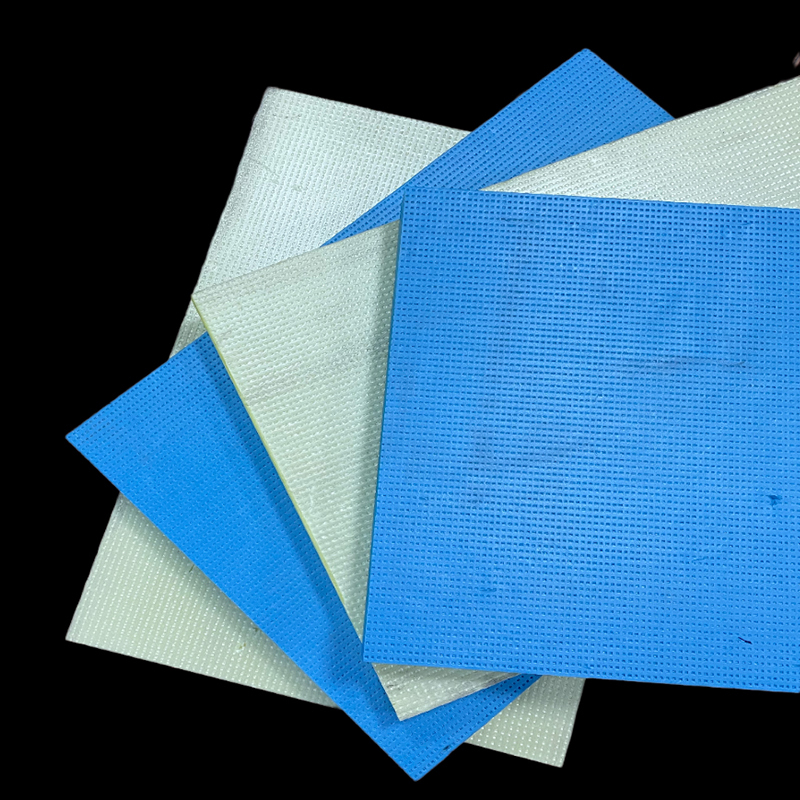

XPS flame-retardant extruded sheet is a hard foamed plastic sheet made of polystyrene resin as raw material, other raw materials and polymers, through heating and mixing, injecting catalyst at the same time, and then extrusion molding. Its scientific name is extruded polystyrene foam for thermal insulation (XPS for short). XPS has a perfect closed cell honeycomb structure, which makes XPS plate have extremely low water absorption (almost no water absorption), low thermal conductivity, high compression resistance and anti-aging (there is almost no aging decomposition phenomenon in normal use). XPS flame-retardant extruded sheet is an insulation material used for wall insulation and roof insulation. It has the characteristics of long-lasting thermal insulation, anti-corrosion, moisture-proof, water resistance, light weight and environmental protection. It is widely used for building roof insulation, steel structure roof, building wall insulation, building ground moisture retention, square ground, ground frost heave control, central air conditioning ventilation duct, etc.

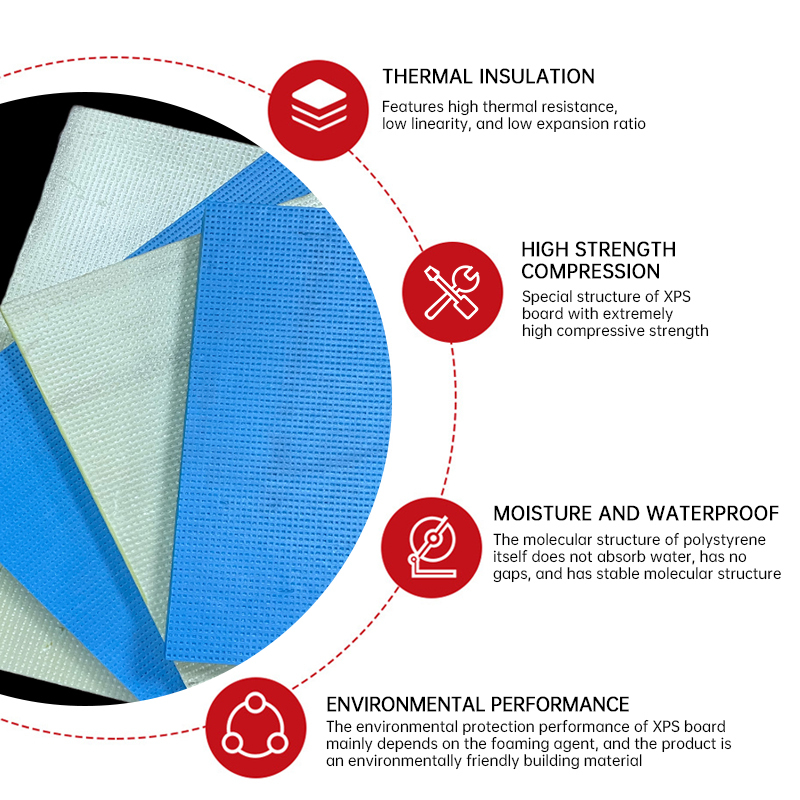

1. Excellent thermal insulation

It has the characteristics of high thermal resistance, low linearity and low expansion ratio. The closed cell rate of its structure reaches more than 99%, forming a vacuum layer, avoiding air flow and heat dissipation, and ensuring the durability and stability of its thermal insulation performance. Compared with the 80% closed cell rate of foamed polyurethane, the leading edge is self-evident.

2. Excellent high-strength compression resistance

Due to the special structure of XPS plate, its compressive strength is extremely high and impact resistance is extremely strong. According to different types and thicknesses of XPS, its compressive strength can reach more than 150 ~ 700KPA, which can bear the ground load of various systems. It is widely used in Geothermal Engineering, expressway, airport runway, square ground, large cold storage and interior decoration and insulation.

3. High quality hydrophobicity and moisture resistance

Water absorption is an important parameter to measure thermal insulation materials. After absorbing water, the thermal insulation performance of the thermal insulation material decreases. At low temperatures, the water sucked in is very easy to freeze, which destroys the structure of the thermal insulation material, thus reducing the compression resistance and thermal insulation performance of the plate. Because the molecular structure of polystyrene itself does not absorb water, the molecular structure of the plate is stable and has no gap, which solves the problems of water leakage, penetration, frost formation and condensation of other materials.

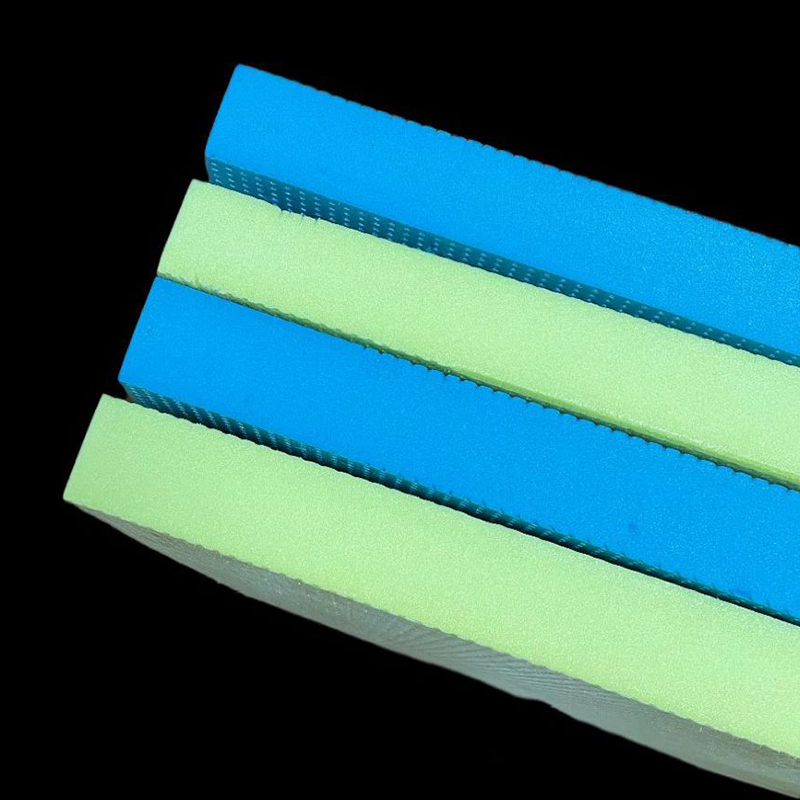

4. Light and easy to use

The fully closed cell foaming chemical structure and the honeycomb physical structure of XPS plate make it light and high-strength, easy to cut and transport, not easy to damage and easy to install.

5. Good stability and corrosion resistance

During long-term use, it does not age, decompose, or produce harmful substances. Its chemical properties are extremely stable, and it will not degrade due to water absorption and corrosion, which will reduce its performance. It can still maintain its superior performance under high temperature environment.

6. Environmental performance of products

The environmental protection performance of XPS board mainly depends on the foaming agent. At present, most domestic manufacturers use CO2 as the catalyst, but some manufacturers have been using freon. It has been tested by relevant national departments that it has stable chemical performance, does not volatilize harmful substances, and is harmless to human body. The raw materials used for production are environmental protection materials, which do not cause any industrial pollution. This product is an environmental friendly building material.

Chongqing Ruilong foam plastic Co., Ltd. was established in 1995. It has more than 80 employees, including 8 middle and senior professional and technical personnel. The company is located in Jinglong Industrial Park, Hangu Town, Jiulongpo District, Chongqing. It covers an area of 20000 ㎡, with a designed annual consumption of 6000 tons of EPS and XPS raw materials and an annual output of 350000 M ³ Finished plate. The company is a large-scale processing enterprise specializing in the production of (EPS) expanded polystyrene board and (XPS) expanded extruded board in Southwest China. The company's products are mainly used for industrial casting. In addition, they are also widely used for wall insulation, exterior wall decoration lines, freezing and cold storage, shockproof and sound insulation.

Pioneering, innovative and enterprising is the enterprise's purpose. At the end of 2011, the company introduced advanced production equipment from South Korea. Which greatly improves the solubility and compressive strength of the product. After years of research and development, the company has formed a stable product production system and process parameters, which greatly improves the stability of products. In the production process, the whole process real-time monitoring is adopted to strictly control and improve the product quality. The lost foam white film produced by the company has the characteristics of good fusion bonding, high compressive strength, low water content and no shrinkage deformation, which fully meets the requirements of automatic digital milling processing of lost foam. With excellent product performance, the lost foam white film produced by the company has successfully occupied 80% of the market share in Southwest China, covering Sichuan, Hubei, Hunan and other surrounding provinces.

The board produced by the company is widely used in the building industry and is the traditional preferred material for energy conservation and insulation. In October 2010, it passed the Chongqing building energy conservation technology filing. In February 2011, it obtained the certification of building energy conservation technology (product) of Chongqing Construction Technology Development Center.

Since its establishment, the company has adhered to the business philosophy of "brand comes from quality and reputation shapes the future", adhered to honesty, brand strategy as a means, customer satisfaction as a goal, and constantly exceeded itself to achieve continuous breakthroughs in product quality.

He Zhenni

506324472@qq.com

Disclaimer: This article is reproduced from other media. The purpose of reprinting is to convey more information. It does not mean that this website agrees with its views and is responsible for its authenticity, and does not bear any legal responsibility. All resources on this site are collected on the Internet. The purpose of sharing is for everyone's learning and reference only. If there is copyright or intellectual property infringement, please leave us a message.

©copyright2009-2020New York Fashion News Contact Us SiteMap