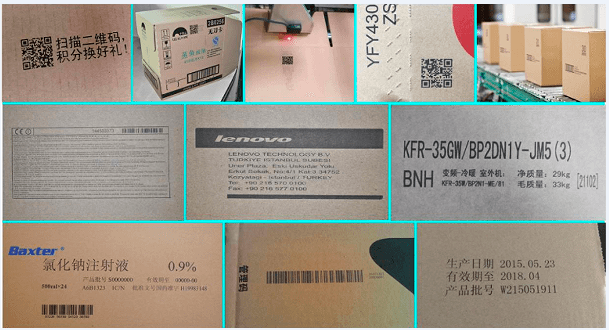

In the carton packaging industry, inkjet printers are often used to print variable data information such as serial numbers, production dates, and batch numbers.There are many types of inkjet printers for carton boxes. At present, the models that can be used for inkjet printing on the outer packaging of cartons include thermal foaming inkjet printers, Drop-on-demand inkjet printers, small character inkjet printers and UV large character online inkjet printers. Inkjet printers are available. However, in practical applications, the content to be printed on the carton is different, and the type of inkjet printer actually selected is also different. For example, if you only need to print a simple production date and other information, then the four models described above can be easily implemented. However, if you want to print high-quality information such as QR codes and barcodes, you need to focus on the recognition rate of QR codes and barcodes. Because the printing accuracy of small character inkjet printer is 70DPI, the printing accuracy of on-demand inkjet printer is 200DPI, the printing accuracy of thermal foaming inkjet printer is 300DPI-600DPI, and the printing accuracy of UV large character online inkjet printer is 300DPI-600DPI. The printing accuracy is adjustable between 200DPI-1200DPI, so what type of inkjet printer to choose also needs to be determined according to the customer's inkjet coding needs.

The two-dimensional code inkjet printer for cartons is mainly a UV inkjet printer. Its advantages are as follows:

The first point: the printing accuracy. The printing accuracy of the UV inkjet printer is high, and the printing accuracy can be set by itself within a certain range. Enterprise users choose UV inkjet printer to ensure high recognition rate of barcodes, QR codes, etc., and do not need to use high-end acquisition equipment, so in practical applications, it is more suitable for enterprise users with large production volumes.

The second point: Micro-embedded UV inkjet printers can be connected to multiple sets of printheads to meet the coding needs of multiple production lines. The printing speed is fast, saving a certain amount of procurement costs for enterprise users.

The third point: the visual effect is good. The UV inkjet printer adopts environmentally friendly UV ink, which meets the adaptability of various materials, and can have good firmness and visual effects on the surface of permeable and non-permeable materials;

The fourth point: UV ink has good adhesion and is environmentally friendly. UV inkjet printer ink generally ensures high adhesion on the surface of the material, which can prevent scratches and waterproofing to the greatest extent.

In the carton coding, when we use the UV Carton Boxes inkjet printer to print variable barcodes or variable QR codes, there are some things to pay attention to:

1. The commonly used material in packaging cartons is silk screen paper, which is different from ordinary white paper. It is necessary to pay attention to the reflectivity of the paper on the corrugated paper, which will affect the identification of barcodes.

2. When selecting inkjet inks, high resolution inkjets printer with good color fastness, low air permeability and moderate ink diffusion should be used to ensure the high quality of barcode spray codes.

3. Attention should be paid to dimensional accuracy when printing corrugated box barcodes. The surface of the carton may not be completely flat, and the force during transportation may be uneven, resulting in the bar code being bent and deformed. The bar code should have a certain range of error tolerance when ensuring accuracy.

4. The bar code has strict requirements on the rod spacing ratio, so it is necessary to ensure the stability of the production line speed. If the speed of the production line changes, all of this can lead to changes in the length of the printed content. For text content, the change in length generally does not affect misreading, but for barcode printing, the change in barcode length will change the blank rate of the barcode, making the code unrecognizable. If it is not possible to ensure the stability of the spraying process, a synchronizer should be configured to ensure that the printing speed of the printer is synchronized with the speed of the production line.

5. Before printing barcodes in batches, a barcode printing test should be carried out to ensure that the barcodes can be scanned and read correctly. Since barcodes must be read with special equipment, unlike reading text information directly with the naked eye, the correctness of barcode content must be checked before mass production to prevent human errors. During the inkjet printing process, random inspections should be carried out regularly.

KeyWords:

thermal foaming inkjet printers

Drop-on-demand inkjet printers

small character inkjet printers

UV large character online inkjet printers

UV Carton Boxes inkjet printer

high resolution inkjets printer

VideoLink:

Disclaimer: This article is reproduced from other media. The purpose of reprinting is to convey more information. It does not mean that this website agrees with its views and is responsible for its authenticity, and does not bear any legal responsibility. All resources on this site are collected on the Internet. The purpose of sharing is for everyone's learning and reference only. If there is copyright or intellectual property infringement, please leave us a message.

©copyright2009-2020New York Fashion News Contact Us SiteMap