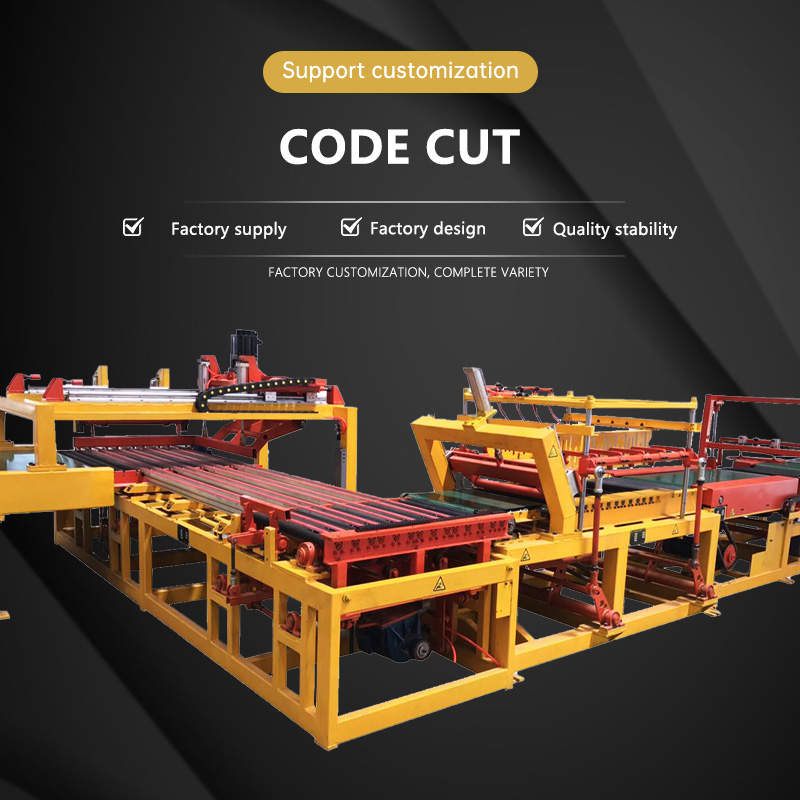

The process route from the extruder's mouth to the kiln car of this production line includes the following equipment: one servo strip cutter, one acceleration belt machine, one multi-functional servo billet cutter, one turning belt machine, one set of automatic servo conveyor, two sets of multi-functional flexible grouping, two sets of automatic billet turning machine, two sets of palletizing robot, and the supporting electric control system. The servo strip cutter picks up the mud strip extruded from the brick extruder and cuts the mud strip according to the required length of the production process, and then the accelerating belt quickly sends out the cut mud strip. Servo strip cutter working process: When the mud strip passes through the belt equipped with rotary encoder, the belt is driven by the mud strip to rotate and count. When the mud bar through the length of the set length after the servo cutter quickly cut off the mud bar, at the same time follow the mud bar speed synchronous walking carriage to ensure that the cut smooth. After the mud strip cutting is finished, the mud strip is sent out through the acceleration belt.

The steel wire of the cutting machine adopts cylinder tensioning, the tensioning effect is good, and it is easy to replace the steel wire. With broken wire detection function, automatic alarm stop and display the corresponding alarm prompt when the wire is broken.

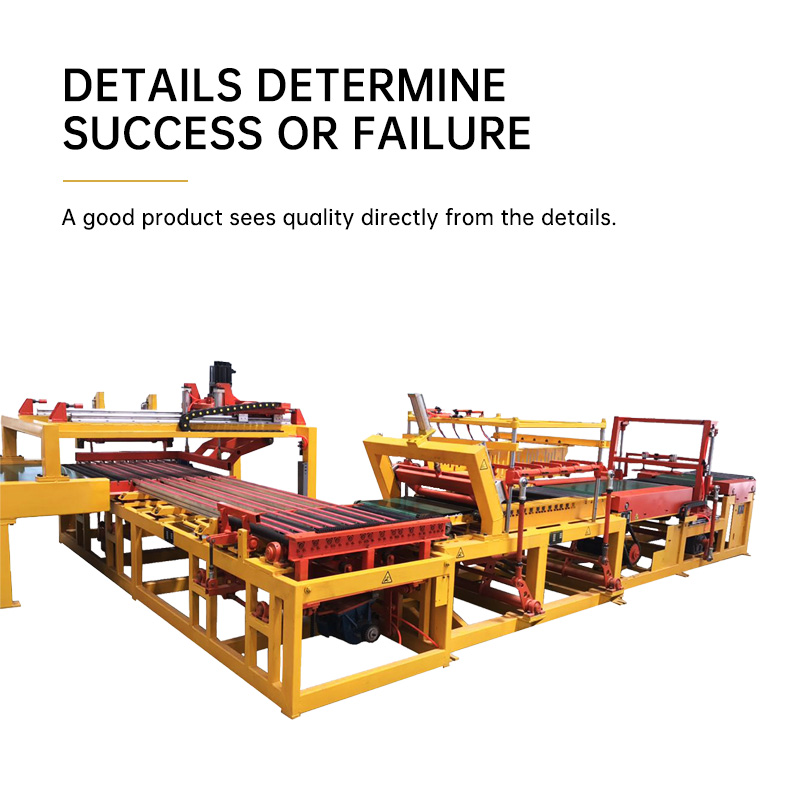

"Before starting the machine: test whether the air source pressure is within the working range, whether the moving parts are well lubricated, and whether there are interfering objects around the equipment. Check the equipment fixed bolt, cutter synchronous belt and rotating counting belt tensioning degree.

When running: It is necessary to find the position of the cutting knife and the origin of the carriage before production, and check whether the position of the reference point is normal after the position finding is completed. During the production process, if there is alarm, shaking and other abnormal conditions, it should be stopped in time.

After stopping the machine: clean up the cylinder rod and the mud and slag on the equipment, check the lubrication of each moving part and make up the oil in time. Discharge the water in the air source processor and clean the environmental hygiene around the equipment. The accelerated belt machine is mainly composed of driven roller, conveying belt, active roller, active motor, bracket and other components, the bracket can be made according to the actual required height. This strip cutter adopts full servo control, so there is no extra photoelectric and proximity switch. It is easy to use and has low failure rate as only the corresponding parameters need to be modified when modifying the length and cutting width of mud strip."

"NOFIT Building Materials Group Co., Ltd. is a modern comprehensive science and technology environmental protection enterprise integrating project design and development, equipment manufacturing, kiln engineering construction and technology output in four parts.

The company is the vice president unit of China Brick and Tile Association, the first to pass the two integration management system assessment, and has won the national high-tech enterprises, national intellectual property rights advantageous enterprises, Sichuan Province Enterprise Technology Center, the national AAA grade integrity enterprise and other honorary titles.

The company has national Grade B engineering design qualification, Grade 3 metallurgical construction general contracting qualification, 18 scientific researchers of intermediate level or above, and more than 190 technical and construction personnel of various types, with strong technical force, advanced processing equipment, and perfect after-sales service system, to provide high-quality products and comprehensive services for customers at home and abroad.

From R&D and production to after-sales service, the company always insists on scientific and environmental protection R&D concept and exquisite processing technology to shape a high quality kiln leader. Our R&D center provides users with engineering and process design for brick making production lines; machinery company provides complete sets of brick making equipment; robotics company provides professional intelligent robots and automation control systems; kiln company builds kilns and engineering construction for users; subordinate brick factories provide intuitive visualization services and provide users with personnel training, installation and commissioning services with rich production experience; technical service center provides plant construction The technical service center provides plant construction, renovation consulting, brick plant technology contracting and operation contracting services. We really realize the "one-stop" service of undertaking projects.

After several quenching, we finally cast a shining brand; a thousand hammers and refinements, forging a fine steel pencil. With strong research and development technology, excellent product quality and quality after-sales service, we will work hand in hand with friends from all walks of life at home and abroad to create the future together! In order to realize the science and technology, industrial prosperity, and continue to climb a new peak!"

Contact Person:Weidong Ma

Email:759280000@qq.com

Disclaimer: This article is reproduced from other media. The purpose of reprinting is to convey more information. It does not mean that this website agrees with its views and is responsible for its authenticity, and does not bear any legal responsibility. All resources on this site are collected on the Internet. The purpose of sharing is for everyone's learning and reference only. If there is copyright or intellectual property infringement, please leave us a message.

©copyright2009-2020New York Fashion News Contact Us SiteMap