1. Most of the pre twisted armour rods are used to reinforce the defective crimping pipe or the conductor with serious strand breakage. The reinforcement is carried out with preformed armour rods, and the two ends are usually fixed by crimping with repair tubes. When crimping the repair pipe, the surface of the repair pipe needs to be wound with detonating cord. Since the detonating cord is manually wound, uneven phenomenon is inevitable. Under the impact force generated by detonating cord explosion, some traces will be left on the surface of the pre twisted wire armour rod, and at the same time, the explosion will also leave a positive impact stress on the pre twisted wire armour rod.

2. Under the action of 4 stresses (conductor normal stress, impact normal stress, alternating normal stress and alternating shear stress), the preformed armour rod will produce extremely fine cracks at the action point of large internal stress or at the place with defects on the surface of the armour rod after more than 10 years of operation (this crack is found on the preformed armour rod with broken strands). The origin of this crack is referred to as the crack source for short. The stress concentration occurs at the root of the crack source, and the number of stress alternations increases with the increase of stress.

3. When installing the pre twisted wire armour rods, the method of explosive crimping with repair tubes at both ends of the pre twisted wire armour rods is no longer used, but the copper wire is used instead, which not only avoids the impact of normal stress on the pre twisted wire armour rods, but also reduces the damage to the surface of the pre twisted wire armour rods. In addition, since the two ends of the preformed armor rod are not fixed, the normal stress of the temperature change of the preformed armor rod can also be reduced, thereby improving the fatigue resistance of the preformed armor rod.

The use of pre twisted wire armour rods is very important. Although it is only a very common structure, it can directly protect and transform the circuit appropriately, greatly improving the safety of electricity use. Some structures inside the pre twisted wire armour rods are very simple and can be easily purchased in the market. They are common and important.

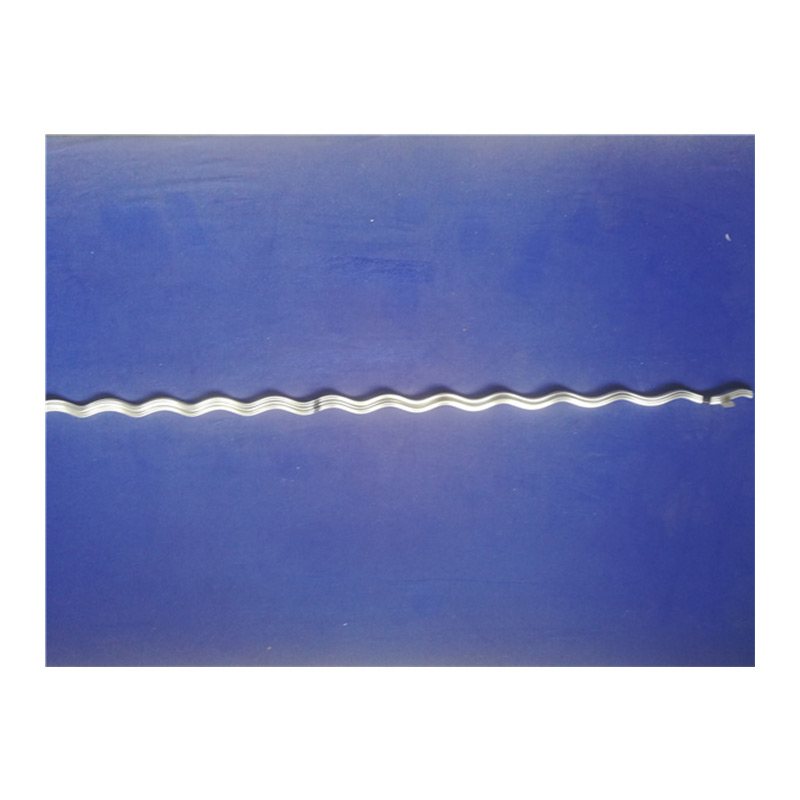

In order to prevent damage at the suspension point of overhead power line due to vibration, the armour rod is added to the wire clamp of the line conductor, so as to enhance the rigidity near the wire clamp, inhibit bending, extrusion stress and wear of the conductor due to vibration, and improve the vibration resistance of the conductor. There are two types of armour rods: tapered and pre twisted. In our country, most of the pre twisted wire armour rods are used as anti vibration protection measures. The pre twisted wire has been included in the hardware products, which is an aluminum magnesium silicon alloy wire. The main reason for the strand breakage of the pre twisted wire armour rods is that the allowable endurance limit of the pre twisted wire armour rods is less than the endurance limit in actual operation, leading to fatigue damage.

The pre-twisted wire fittings successfully developed by the company are widely used in power grid communication lines, power grid transmission and distribution lines, communication transmission lines, electrified railways and transportation power lines, etc. process of modernization.

Pre-twisted fittings are the most widely used overhead line installation fittings in developed countries in the world. They have the advantages of light weight, simple and convenient installation, uniform grip, firmness and reliability, corrosion resistance, heat resistance, energy saving and environmental protection. Comparable performance.

The company takes the development of my country's electric power industry as its own responsibility, and takes "customer satisfaction" as the ultimate goal of all the work of the company. Always adhere to the quality policy of system management, full control, sincere service, and quality-based enterprise. Take "unity, innovation and integrity" as the business philosophy of the company, and constantly surpass ourselves, as the enterprise spirit we believe in from beginning to end.

Feng Deng

dengfeng8451@gmail.com

1030286832@qq.com

Disclaimer: This article is reproduced from other media. The purpose of reprinting is to convey more information. It does not mean that this website agrees with its views and is responsible for its authenticity, and does not bear any legal responsibility. All resources on this site are collected on the Internet. The purpose of sharing is for everyone's learning and reference only. If there is copyright or intellectual property infringement, please leave us a message.

©copyright2009-2020New York Fashion News Contact Us SiteMap